9 Pain Points in Traditional Manufacturing

1、Surging pressure on human resource cost, urgent need to realize less humanization.

2、Low operational performance and low profitability of enterprises

3、High pollution, high energy consumption

4, the lack of effective business management and data management system, unable to quickly respond to market changes

5、Insufficient innovation ability, products are mainly imitated, competitiveness needs to be improved

6, product quality and reliability is not high 7, urgent need to expand manufacturing services, innovative business model

8, the lack of collaboration between upstream and downstream enterprises, information opacity

9, the application of information systems and automated production lines, but there are still a lot of dumb equipment, silos, lack of flexibility

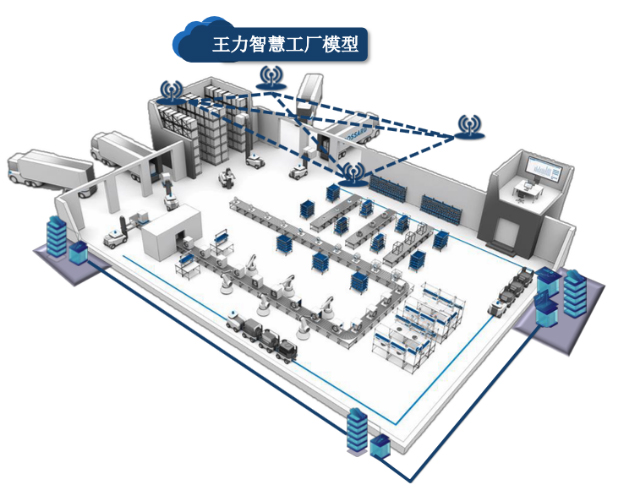

Benefits of Management Intelligence Strategy for Wonly

Increased productivity of the production line by about 40% or more

Intelligent manufacturing throughout the process of intelligent equipment (including but not limited to robots, CNC machine tools, automation integration equipment, etc.) through the communication technology organically connected to achieve automation of the production process; and through a variety of sensory technology to collect a variety of data in the production process, through industrial Ethernet and other means of communication, as well as all kinds of system optimization software to provide production solutions, to achieve the production of intelligent production solutions to improve production efficiency 40% or more

Production cost reduction of about 30%~40%

Intelligent manufacturing integrates “intelligence” into every aspect of the enterprise's orders, supply chain, production, sales and service, creating a flexible supply chain, thus intelligently saving labor costs and reducing production costs by 30%~40%.

Reduced time-to-market by approximately 30% or more

Design and test products through engineering simulation technology, thus accelerating the product development and analysis process and shortening the product development and testing cycle by more than 30%.

Reduce labor costs by about 30%~40%

Through the MES system to send out the command information, the corresponding materials from the automatic silo transport to the loading and unloading point, automatic loading and unloading to realize the intelligent, efficient, accurate and safe transport of materials in the workshop, thus reducing more than 50% of the time wasted on the change of line.

Reduce labor costs by about 30%~40%

Through the application of intelligent warehousing system WMS, intelligent logistics system TCS, AGV, robots and other intelligent manufacturing equipment, while helping enterprises optimize production and improve product quality, it has helped enterprises reduce labor costs by about 30% to 40%, and increased profits.

Reduce energy costs by about 20% or more

Utilizing the information interaction between various production systems to realize the digital production of the whole process, and realizing the visualization of energy consumption, energy leaning and integrated management through online energy monitoring, thus reducing the energy consumption by more than 20%.

Improvement of production by about 70% or more

In intelligent manufacturing factories, people, machines and resources naturally communicate and collaborate with each other. The use of “intelligent robots” reduces the number of workers, and the production line management mode is shifted from the original management of people to the management of equipment, which realizes a 70% increase in production capacity.

Quality improvement of about 90% or more

Intelligent automated production line replaces traditional manual production with machine operation, which greatly eliminates product errors and improves product precision, and quality is improved by about 90% or more.

Reduces equipment downtime by approximately 80% or more

Real-time insight into the state of equipment through the IOT monitoring system, help equipment managers real-time insight into equipment failure, abnormal performance, timely elimination of equipment health hazards, thus reducing equipment downtime by more than 80%.

Reduce operational accident costs by approximately 85% or more

Reduce accident costs by more than 80% by allowing robots to perform hazardous tasks in extreme environments, thereby drastically reducing the number of operational accidents.

Management Intelligence Strategy 4 Advanced

1、Wonly Group Informationization Overall Planning Chart-Advanced Architecture

Group Level

1.BOM management (definition, planning, design)

2. Material management (definition, coding)

3. Process design (route design, process organization)

4. Vendor management (procurement, quality, payment)

5. Customer (dealer) management

6.Regulations

Base Level

1.Production planning management

2.Quality management planning (incoming materials, finished products, semi-finished products)

3. Equipment management planning (planning, maintenance)

4.Product traceability

5.In-process management

6.Work order management

Group Level

1.Production execution

2.Quality control

3.Workstation reporting

2, the application of new technologies - technology to lead the development of the door industry - advanced information technology

Edge Computing Technology

On the side of the data source, an open platform integrating network, computing, storage, and application core capabilities is adopted to provide the nearest services.

Usage Scenarios: Changtian Factory Data Bus; Sichuan Wooden Door Factory; Smart Park Video System

Technology I

Novel Sensing Technologies

Utilizing high sensing sensitivity, accuracy, reliability and environmental adaptability of the sensing technology, the sensing signal extraction and processing.

Usage Scenario: Longtim factory production line loading and unloading sensing device; Sichuan wood door factory plate sensing, such as carving line

Technology II

Advanced Control and Optimization Technology

Modeling technology based on a large amount of data, large-scale high-performance multi-objective optimization technology, equipment simulation technology, electronic drive precision motion control technology, etc. Scenarios: PLM system; APS system, MES system, ERP system, etc.

Technology III

Internet of Everything technology

The Internet of Everything (IoE) is defined as the combination of people, processes, data and things that make network connections more relevant and valuable. Usage Scenario: MES system, data bus EAP system, intelligent campus

Technology IV

Digital Twins

Modeling technology based on large amounts of data, large-scale high-performance, multi-objective optimization technology, equipment simulation technology, electronic drive precision motion control technology Scenarios: PLM systems; Tecnomatix systems, logistics systems

Technology V

Highly reliable real-time communication network technology

Highly reliable and scalable communication network construction technology (5G technology), industrial communication network information security technology, and cloud technology to realize seamless information exchange between heterogeneous networks.

Usage Scenarios: Ali Data Center; Graffiti Platform; Intelligent Park; Changteng and Pengxi Factory in Sichuan Province.

Technology VI

Artificial Intelligence Technology (AI)

Relying on industrial Internet of Things (IOT) technology, cloud computing technology, and big data analysis technology, it analyzes, judges, and makes decisions on the smart manufacturing process, and realizes that industrial manufacturing operates in a flexible, efficient, and energy-saving way.

Usage Scenario:Intelligent Park Gate, Road Gate, Ladder Control System, CCD Identification

Technology VII

Internet of Things (IoT) technology

It refers to the realization of intelligent perception, identification and management of goods and processes through various information sensors, radio frequency identification technology and other devices and technologies.

Scenario: Changtian and Sichuan factories logistics handling system, intelligent production lines, intelligent parks.

Technology VIII

Big Data technology

It refers to the application technology of big data, covering all kinds of big data platforms, big data index system and other big data application technology

Usage Scenario:Ali Data Center;Graffiti Platform

Technology IX

Cloud Technology

Cloud technology refers to a hosting technology that unifies hardware, software, network and other resources within a wide area network (WAN) or local area network (LAN) to realize data computing, storage, processing and sharing.

Usage Scenarios: Ali Data Center; Graffiti Platform.

Technology X

3. Win-win cooperation -- advanced information technology